Ready to transform your woodworking projects from amateurish to awe-inspiring? The key lies in mastering your miter saw. This versatile tool, capable of making both angled and straight cuts, can elevate your craftsmanship to new heights. To truly unlock its potential, though, precision is paramount.

Start by ensuring your blade is sharp and properly aligned. A dull blade will snag and create uneven cuts, while a misaligned one will introduce errors into your angles. Fine-tune your fence to ensure it's firmly secured and perfectly perpendicular to the blade.

- Utilize a miter saw guide for accurate angled cuts, ensuring consistency across multiple pieces.

- Practice making test cuts on scrap wood before tackling your final project. This allows you to calibrate your settings and gain confidence in your technique.

- Feed your workpiece steadily and smoothly through the blade, avoiding any jerking motions that can lead to inaccuracies.

Remember, mastering a miter saw takes practice and patience. But with dedication and attention to detail, you'll be crafting precise cuts like a pro in no time.

Mastering Upcut Saws for a Polished Carved Finish

Achieving a polished finish when carving wood often hinges on the precision of your upcut saw techniques. An upcut saw, with its teeth angled to shear upwards, is especially valuable for removing material and creating a clean surface.

- Utilize light, controlled pressure when making your cuts to minimize tearing or splintering of the wood.

- Direct the saw in a steady and consistent motion to ensure an even cut throughout the workpiece.

- To alleviate tearout, incorporate a sharp saw blade that is specifically designed for carving.

Remember, practice makes perfect when it comes to mastering upcut saw techniques. Experiment with different speeds and pressures to find what works best for you and the specific type of wood you're working with. With time and dedication, you can achieve beautifully smooth finishes that enhance your carved creations.

Picking the Right Saw for Your Project Needs

Embarking on a new DIY project? Selecting the appropriate saw is vital for securing success. Different saws are built for specific more info tasks, so identifying your project's needs is paramount. A heavy-duty circular saw might be suitable for cutting through thick lumber, while a delicate jigsaw shines when navigating intricate curves. Evaluate the substance you'll be working with and the sophistication of your cuts. A detailed understanding of these factors will lead you to the saw that effectively complements your project.

- Circular saws

- Hand saws

Mastering the Art of Saw Usage: A Comprehensive Guide to Types and Uses

Entering the world of saws can feel intimidating. With a plethora surrounding different types, each designed for specific tasks, it's easy to get overwhelmed. This guide aims to illuminate the diverse sphere of saws, providing you with the knowledge to select the perfect tool for your needs and confidently tackle any cutting task.

From the robust band saw, ideal for lumber even sheet products, to the precise coping saw, perfect for intricate cuts, this guide will explore the unique capabilities of each type within saw. You'll learn about their applications, common uses, and essential security precautions to ensure a smooth and successful sawing experience.

- Discover the capabilities of various saw types, including reciprocating saws, miter saws, and table saws.

- Comprehend the appropriate uses for each saw type, ensuring you choose the right tool for the job.

- Become adept at safe sawing practices to prevent accidents and injuries.

CNC Machine Accuracy: Taking Woodworking to New Heights

The woodworking industry has undergone a significant transformation in recent years with the advent of CNC tools. These sophisticated machines utilize computer-aided design to carve and shape wood with unparalleled precision, elevating the art of woodworking to new standards.

CNC machines boast incredible accuracy, enabling craftsmen to create intricate designs and complex geometries with ease. This level of accuracy minimizes the need for manual adjustments, leading to a faster production process and fewer errors.

- CNC machines allow for the creation of highly reproducible pieces, ensuring that each product meets strict quality.

- The ability to program intricate designs into CNC machines opens up a world of options for woodworkers, allowing them to push the boundaries of their craft.

- From furniture making to architectural millwork, CNC technology is transforming the woodworking industry, offering unparalleled accuracy and output.

Unlocking Potential: The Power of a CNC Router for Custom Designs

A Computer Numerical Control (CNC) router is an impressive tool that can revolutionize the way you approach custom designs. These machines offer unmatched precision, allowing you to bring your imaginations to life with incredible skill. From intricate wood carvings to complex plastic prototypes, a CNC router unlocks a world of possibilities for craftsmen of all levels.

With its ability to execute digital designs, a CNC router reduces the need for manual labor, guaranteeing consistent and repeatable results.

- This frees up your time to devote on the artistic aspects of your work.

- ,Additionally, the versatility of a CNC router extends beyond traditional materials, allowing you to work metals, composites, and even foam with ease.

Whether you're a seasoned professional or just starting out, investing in a CNC router can be a transformative move in your creative journey. It empowers you to push the boundaries of what's possible and create truly unique pieces that express your individual style.

Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Sam Woods Then & Now!

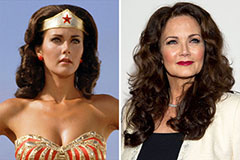

Sam Woods Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Heather Locklear Then & Now!

Heather Locklear Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!